High Purity Chemical Dispense System & Packing System

Chemical classification:

-

Acid chemicals

-

Alkaline chemicals

-

Organic solvent chemicals

feature of product

1. Chemical classification:

- Acid chemicals

- Alkaline chemicals

- Organic solvent chemicals

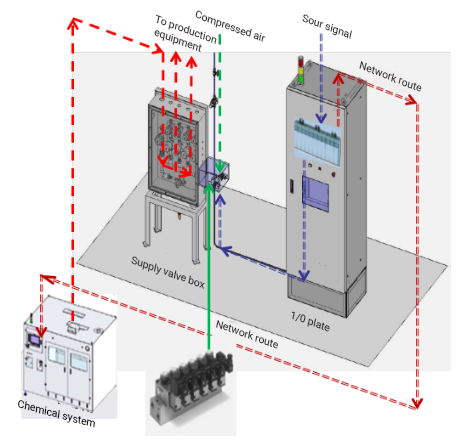

2. Chemical system unit architecture:

- Storage tank: located in the factory area, used for temporary storage of chemicals, equipped with a level gauge, real-time notification of the staff on duty to replenish chemicals

- Supply equipment: set up in the factory area, used for chemical supply/transportation/dilution/purification

- Distribution valve box (VMB): located in the clean room, distribute chemicals to multiple production machines

- I/O Panel: located in the clean room, used as a communication interface between the production machine and the acid supply machine

- DCP (Main PLC Panel): located in the factory area, used as I/OPanel/for acid machine/SCADA signal exchange

- SCADA (Supervisory Control System): Set in the factory area, monitor the operation status of each I/OPanel/acid supply machine/VMB, and send out real-time alarms and record the system status

- Piping system: For chemical transportation, it can be divided into PFA or SUS or PV according to the characteristics of chemicals

- UTILITY: Power/N2/CDA/UPW/EXH/Drain.. for the acid machine.

Application field

1.Lorry Supply System:

- The design of lorry supply system requires corrosion-resistance PFA material for the lighting, pressure gauges, nitrogen guns, water guns, N2 safety valves, tank pressure sensors and other safety facilities, valves, fittings and pipes.

- A well-designed exhaust system also requires ppt grade pipes and fittings.

- Design high-efficiency PTFE filtration to ensure a cleanliness level of operating space; design sampling ports for inline inspection and quality control for laboratory.

- The control system adopts PLC design, touch panel, and barcode scanner (for misoperation prevention). The operation panel design is user-riendly for its conveniency and safety duing operation.

- Leakage detector is installed for chemical supply safety monitoring; transparent window design for maintenance easiness.

- The organic chemical dispense system will provide CO2 units, temperature detectors and flame detectors.

2. Transfer/ Supply System:

- Design lighting, pressure gauges, nitrogen guns, water guns, N2 safety valves, storage tank pressure sensors and other safety facilities.

- Valves, fittings and pipes should be made of corrosion-resistant PFA material.

- Well designed exhaust system.

- The pipe fittings are made of ppt grade material.

- Design high-efficiency PTFE filtration to ensure a cleanliness level of operating space.

- Design sampling ports for inline inspection and quality control for laboratory.

- The control system adopts PLC design, touch panel, and barcode scanner (for misoperation prevention).

- Consider the ease of operation of the operation panel.

- Consider the safety during operation.

- Leakage detector is installed for chemical supply safety monitoring.

- Transparent window design for maintenance easiness.

- Organic chemical dispensey system will provide CO2 unit, temperature detector and flame detector.

3. Dilution Supply System:

- Design lighting, pressure gauges, nitrogen guns, water guns, N2 safety valves, pressure sensors and other safety facilities.

- Valves, fittings and pipes shall be made of corrosion-resistant PFA material.

- Well designed exhaust system.

- The pipe fittings are made of ppt grade material.

- Design sampling ports for inline inspection and quality control for laboratory.

- The control system adopts PLC design, touch panel, and barcode scanner (for misoperation prevention).

- The operation panel design is user-riendly for its conveniency operation.

- Consider the safety of the operating process.

- Leakage detector is installed for chemical supply safety monitoring.

- Transparent window design for maintenance easiness.

- Dilution design: BATCH type: high-precision weight ratio measuring + pump loop + high-precision concentration measuring.

- ONLINE type: high-precision flow meter + STATIC MIXER + high-precision concentration measuring.

4. Electronic grade chemical production and dispensing system:

- The design is corrosion-resistant, leak-proof, strong enough, and easy to maintain and operate.

- Valve parts, joints and pipes must be made of corrosion-resistant PFA material.

- Well-designed exhaust device interface.

- The pipe joints are made of materials that meet the ppt grade.

- Leak detector function.

- Transparent maintenance and inspection window design.

- Explosion-proof design (organic).