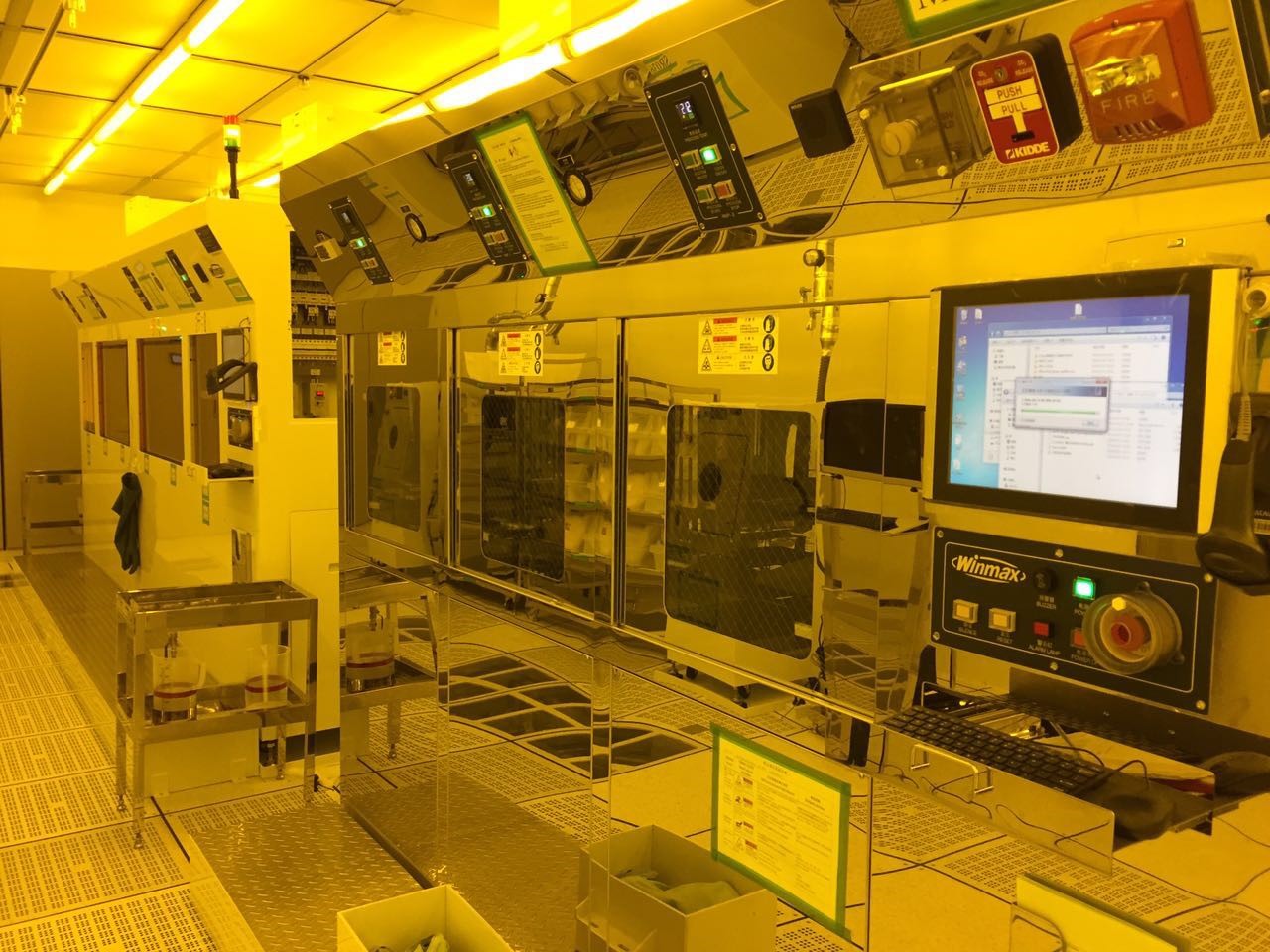

High Purity Wet Bench System

Specialty

-

Wafer Cleaning

-

Wet etching / Development

-

Wet stripping equipment

Equipment product features

1.Wafer Cleaning:

- High-efficiency FFU and exhaust system, highly clean and safe environment, meeting ISO Class 3 cleanliness standards.

- High cleanliness performance after cleaning.

- The wafer can be dried in and out with various drying techniques such as Maragoni Dryer or online spin dryer.

- Highly precisive automatic acid mixing.

- Reach processing temperature quickly and control temperature precisely.

- Full-auto, semi-auto, manual operation of full range customized models.

- Modular design is easy to maintain, reducing maintenance costs.

- 12”, 8”, 6”, 4” wafer cleaning of various sizes.

2.Wet etching / Development:

- High-uniformity etching and developing.

- Achieve ultra-high uniformty control with special mechanical system.

- Tank flow field control technology.

- Highly precisive automatic dosing / replenishing system.

- Chemical concentration monitoring system.

- Highly precisive temperature control system.

- High-efficiency chemical reclaim system.

- Full-auto, semi-auto, manual operation of full range of customized models.

- Modular design is easy to maintain, reducing maintenance costs.

- 12”, 8”, 6”, 4” wafer cleaning of various sizes.

3.Wet stripping equipment:

- Equipped with high-efficiency filtration, no sticky back and no residue.

- Accelerate the stripping speed with the shaking mechanism and ultrasonic device.

- Safety and stability heating system for flammable chemicals.

- Saving chemicals by recycling of cleaner chemicals.

- Flammable chemicals are compliance with fire safety by equipping with full-auto CO2 fire protection system and cut-off exhaust system.

- Full-auto, semi-auto, manual operation of full range of customized models.

- Modular design is easy to maintain, reducing maintenance costs.

- 12”, 8”, 6”, 4” wafer cleaning of various sizes.

4.Other application systems and equipments:

Industry application:Optoelectronic integrated circuit、Advanced packaging process、IC integrated circuit、Photovoltaic industry、Micro-electromechanical product process.

- Heat exchange system-Heat-exchanging area: 0.25 ~ 80 m².

- Inline deionized water heating system (Hot DI system)-System power: 30~ 120 Kw.

- Inline quartz heater-Heating power: 2 ~ 6 Kw, flow rate: Max. 30LPM.

- Parts cleaning machine-Customized equipment.

- Silicon materials cleaning system-Silicon bricks, silicon ingot cleaning. Customized equipment.

- Maragoni Dryer-Low breakage Rate, high cleanliness.

- Hot Nitrogen drying system-Low cost and high efficiency.

- Special chemicals supply cabinet and reclaiming system (Local CDS & Reclaim)-Applicable to various chemicals、Applicable to various specifications of raw material drums、The chemical tank can be automatically switched and supply the chemical continuously、Flammable chemicals are compliance with fire safety by equipping with full-auto CO2 fire protection system and cut-off exhaust system

Application field

1. Wafer cleaning:

- Industry applications: IC integrated circuits, optoelectronic integrated circuits, advanced packaging processes

- Process application: RCA cleaning, cleaning before chip feeding, cleaning before epitaxial wafer, cleaning before shipment of epitaxial wafer, cleaning after etching and cleaning of various process sections

2. Wet etching/development:

- Industry application: advanced packaging process, optoelectronic integrated circuit, micro-electromechanical product process, IC integrated circuit

- Process application: TiW etching, Au etching, Nitride etching, ITO etching and other high-end package development

3. Wet peeling equipment:

- Industry applications: advanced packaging process, optoelectronic integrated circuits, IC integrated circuits

- Process application: wet film removal (removal of photoresist), dry film removal (removal of photoresist), wax cleaning