The global industrial environment is evolving rapidly, as climate change and environmental pollution exacerbate resource scarcity, posing a serious threat to the Earth's long-term sustainability. Novatech actively deploys green engineering, invests in circular economy technology development, and incorporates product innovation into its material topics.

In 2024, Novatech actively promoted cross-sector collaboration with external organizations to enhance resource reuse and overall efficiency. Through its representative engineering projects, the Company provides customers with high-quality environmental pollution prevention technology, supporting the

reduction of their environmental footprint.

Adhering to the concept of sustainable operations,Novatech takes pract i c al actions to develop environmentally friendly products. Through green design, green procurement, and green technology, we utilize innovative methods and rich practical experience to develop innovative products that meet environmental safety and quality standards. We offer engineering technical services for energy conservation, carbon reduction, and resource recycling, while contributing to the sustainable development of enterprises. In the future, Novatech will continue to advance its role in circular economy, aiming to become our customers' preferred partner in achieving efficient, non-toxic, and zero-waste processes through advanced environmentally friendly engineering technologies.

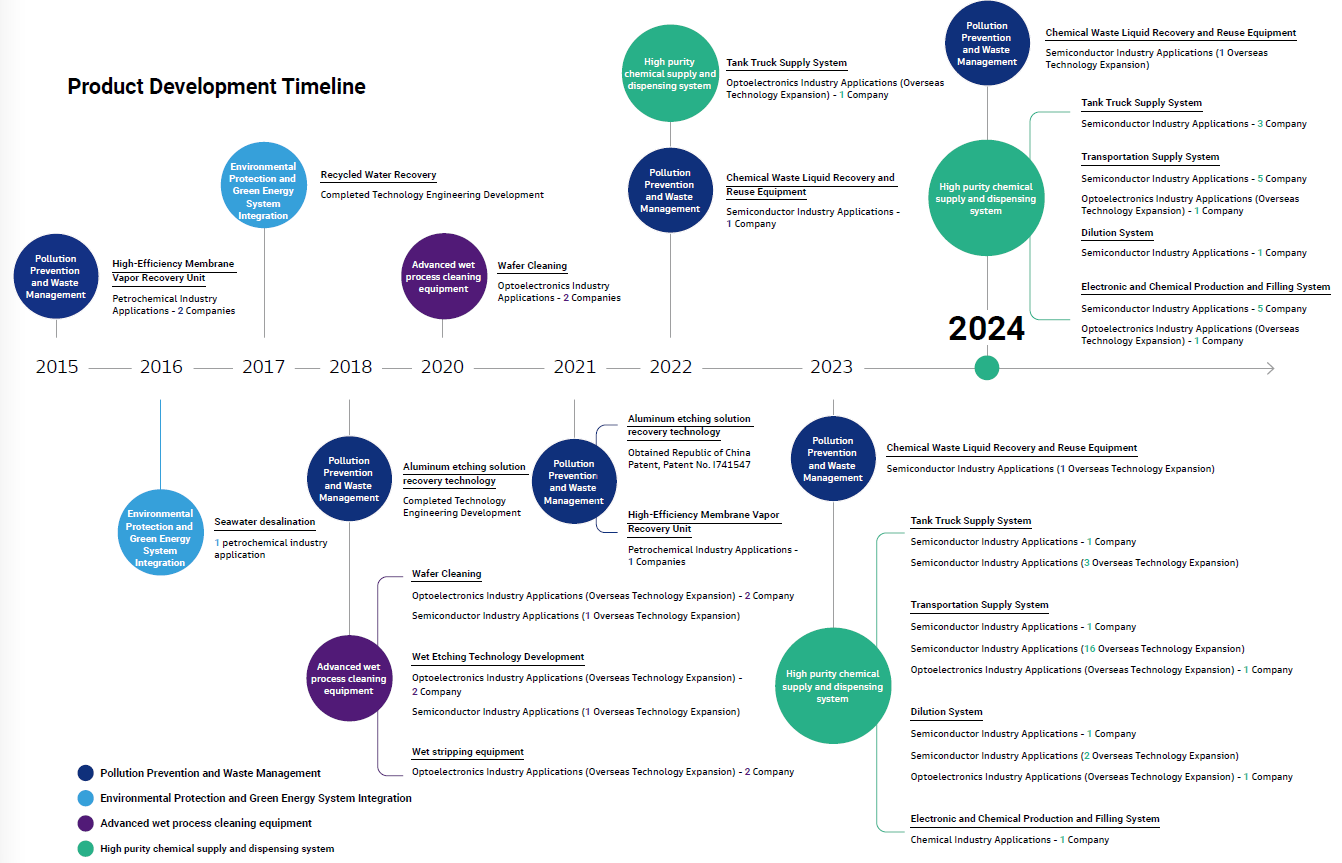

Product Development Timeline

Sustainable Product Innovation ┃ Management Approach

Significance and Meaning to the Company

- The company's research and development of environmental friendly products and services encompasses the management of toxic and hazardous substances in the manufacturing process and conflict minerals policies, ensuring no negative impacts on human health, the environment, and human rights that could compromise customer health and safety.

-

Describe the company's process for evaluating and managing environmental risks in projects and disclose the number of cases that violated environmental permit standards or regulations.

- Describe the company's facility life cycle assessment implementation, including the number of projects certified under third-party sustainability standards

- and the process of incorporating operational energy and water efficiency into project planning and design.Disclose the total amount of fossil fuel-related projects and renewable energy-related projects under construction, the total amount of cancelled or reduced fossil fuel-related projects, and the total amount of non-energy projects related to climate change mitigation.

Action Plans/Resources

- Continue progress by utilizing R&D capabilities and personnel to drive the development of advanced technology products.

- Process optimization projects are undertaken by R&D resources and development personnel.

Management Strategies

- Establish an Environmental Protection and Green Energy Project Department to provide product design and services for emerging needs.

- Develop new engineering project procedures and operational specifications in response to market shifts and requirements.

- Promote green supply chain management to provide customers with hazard-free green products.

Policy/Commitment

- Engineering design control procedures, customer complaint handling procedures.

Description of actual and potential negative and positive impacts

Positive:

-

Provide sustainable products and services such as green product design and waste gas treatment, aligning with environmental protection and energy conservation trends,meeting customer needs, and reducing environmental impact.

Negative:

- Failure to meet product environmental protection and energy conservation requirements may impact customer orders and misalign with market trends.

* This material topic has no actual activities or business relationships involving negative impacts in the current year.

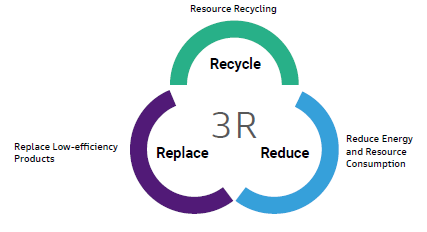

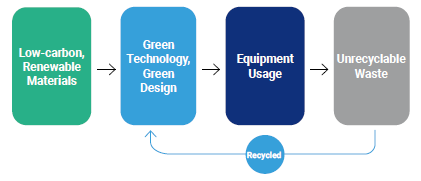

Implement green design

To address the risks and opportunities brought by global climate change and fulfill customers' green commitments, Novatech applies its core corporate capabilities to green product innovation.Green design includes material procurement, production process design, usage, waste recycling, reuse, and treatment,fundamentally preventing pollution while conserving resources and energy. Comprehensively promote product green transformation,focusing on Recycle (resource recycling), Replace (replacing lowefficiency products), and Reduce (reducing resource consumption)products. Build low-carbon competitiveness through the 3R strategy and develop environmentally friendly and non-toxic green products to maintain sustainable environmental development.

Green Product Innovation

Reuse Design

Research green technology

In response to market trends and the global emphasis on low-carbon transportation development, Novatech continues to invest in enhancing technical capabilities

and product innovation through R&D, actively promotes quality management upgrades, and collaborates with the supply chain for low-carbon transformation. The

Company is dedicated to achieving sustainable growth by launching more green energy products integrated with high-quality service.

We embrace a spiri t o f continuous research,development, and innovation, constantly improving energy conservation and waste reduction efficiency.

While delivering the safest and highest quality engineering planning services to our customers, we also prioritize mitigating environmental impacts. In line

with customer requirements, we design specifications above industry-average standards to enhance system resource efficiency during the usage phase. We believe

that the Environmental Protection and Green Energy Group represents a future trend. By utilizing innovative approaches and practical experience, we provide

customers with high-tech process supply systems for circular economy across different industries. While specializing in the semiconductor industry, we also aim

to expand our business into other sectors.

Environmentally friendly products or services

High-tech process supply system transitioning towards a circular economy

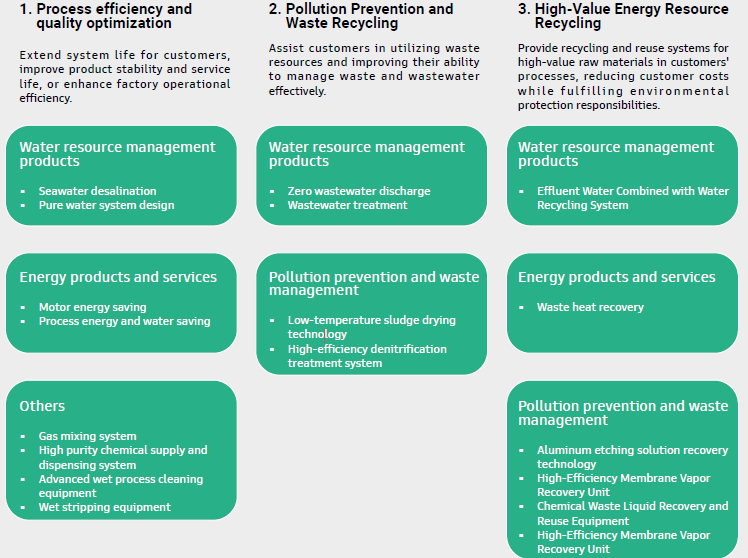

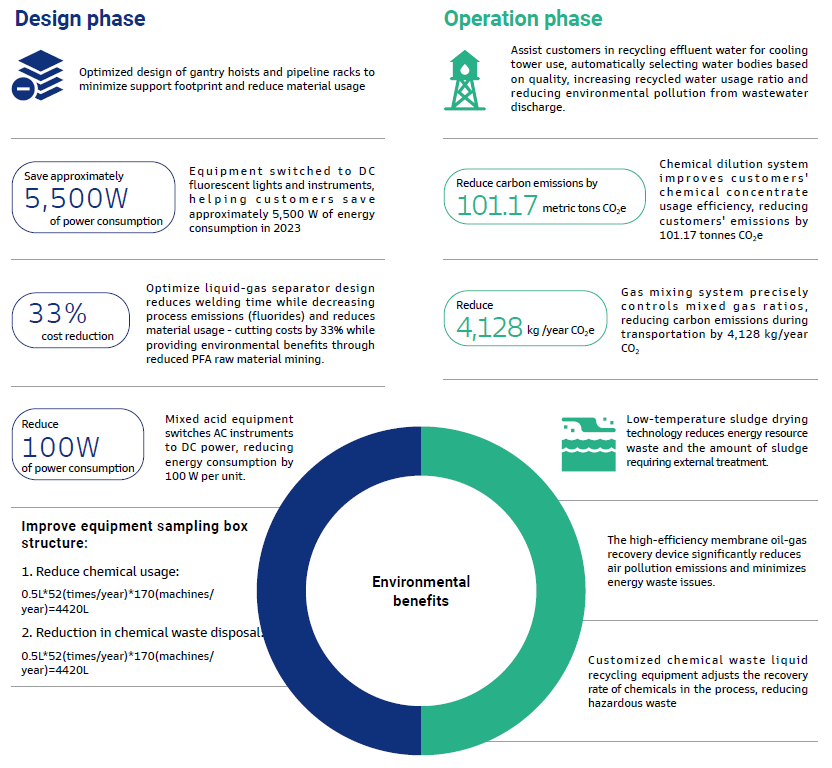

To enhance energy conservation and waste reduction efficiency, Novatech investigates various system optimization across both design and operation phases. We evaluate different methods to improve environmental benefits at each stages of various systems, striving to achieve system perfection.

Process efficiency and quality optimization

Improving resource utilization efficiency and optimizing product processes have always been our core focus. Novatech aims to provide customers with high-precision, stable process systems that enhance factory resource efficiency and extend the lifespan of process equipment. Over the past two years, we have optimized numerous designs to improve performance, such as replacing machine lighting systems with energy-saving lamps, which is expected to reduce power

consumption by 75%. Leveraging years of engineering design expertise, Novatech continues to develop the most efficient and highest-quality processes for our customers.

- Gas mixing system

This product precisely controls mixed gas ratios through a gas mixing system to provide high-quality gases that meet process requirements. It can replace the use of mixed gas cylinders in technology factories, reducing customers' unit gas costs and lowering carbon emissions from gas cylinder transportation.

Based on previous engineering experience, our gas mixing system helps customers reduce carbon emissions from transportation by 4,128 kg/year CO2 and also saves customers approximately 2.5 million in special gas production costs.

- Installation of gantry hoists and pipeline installation optimization design

Novatech’s professional engineers perform gantry hoist load calculations and optimization for areas with the densest onsite piping in customer facilities, following piping construction guidelines. Without compromising functionality or safety, this approach reduces the footprint of pipe support structures and material usage. Faster material delivery and optimized construction schedules further enhance spatial efficiency and lower costs for customers’facilities.

- Machine using DC fluorescent lights and instruments

Traditional floor-mounted machines typically use 15W AC fluorescent tubes, which consume significant power. To help customers achieve energy savings and reduce carbon emissions,Novatech replaced the internal lighting systems with 5W DC fluorescent tubes, reducing power consumption and extending service life. Additionally, for mixed acid equipment, AC-powered instruments were converted to DC power without changing functionality, reducing power consumption by 100W per unit.In 2023, Novatech helped customers save approximately 5,500W of power. Through these measures, Novatech effectively lowered greenhouse gas emissions from machines while minimizing customers’ waste output, actively supporting energy conservation and carbon reduction efforts.

- Gas-liquid separator optimization

Due to the different densities of gas and liquid, when liquid and gas flow together, the liquid will be affected by gravity,producing a downward velocity, while the gas continues to flow in its original direction. In other words, liquid and gas tend to separate in a gravitational field. The design of this product utilizes gravity settling to separate gas and liquid, making customer process applications more stable. The optimization and improvement benefits of the gas-liquid separator can

increase system supply performance by 4%-10% flow rate under different operating pressures, reduce welding time for manufacturing personnel, and reduce waste gas (fluoride) emissions during processing. Reducing material usage not only decreases cost expenditure by 33% but also provides environmental benefits by reducing PFA raw material mining.

- Chemical dilution system

Novatech helps customers establish safe, automated, and precise chemical dilution systems to improve the efficiency of chemical concentrate usage and reduce the impact of highly toxic chemicals. Taking the semiconductor industry as an example, their processes require dangerous chemicals such as developers, hydrofluoric acid, and tetramethylammonium hydroxide. We assist semiconductor customers in establishing P6 hydrofluoric acid chemical dilution systems, which can automatically dilute 168,000 liters of chemicals per year.This not only reduces the risk of manual acid replacement but also decreases chemical drum usage and transportation for customers. In total, it can help customers reduce CO2e emissions by 101.17 metric tons annually.

- Equipment sampling box structural design

In 2024, Novatech introduced equipment manufacturing standards for high-purity chemical supply systems, improving the equipment sampling box structure to reduce sampling leakage opportunities and enhance sampling environment cleanliness. Using new construction methods to improve box extraction efficiency, after product revision:

1. Reduction in chemical usage:0.5L*52(times/year)*170(machines/year)=4420L

2. Reduction in chemical waste disposal:0.5L*52(times/year)*170(machines/year)=4420L

3. Increase equipment operational safety and sampling efficiency, reduce chemical usage, while also decreasing chemical waste disposal volume, enhancing green innovation competitiveness.

Pollution Prevention and Waste Recycling

Pollution prevention and waste recycling have become increasingly important in recent years. Novatech aims to help customers make better use of waste through its

technologies and enhance their ability to properly manage waste and wastewater, further promoting the circular economy in high-tech manufacturing. Our key technologies include effluent water recycling systems, low-temperature sludge drying technology, high-efficiency denitrification treatment systems, and high-efficiency membrane oil and gas recovery devices.

- Effluent Water Combined with Water Recycling System

Water recycling and reuse has become an industry trend in recent years. The ratio between wet and dry seasons in domestic regions is extreme, and during dry seasons, agricultural water often needs to be reallocated, and domestic water supply pressure reduced in order to maintain stable industrial water supply. Therefore, in line with domestic government policies,Novatech actively participates in government water engineering tenders and applications of water recycling systems in

engineering projects. By integrating wastewater plant effluent with recycling systems, we enable the reuse of discharged water for industrial purposes, providing stable and reliable water sources to industrial and science parks with high water demand.This approach reduces reliance on tap water and supports zero liquid discharge.

Based on recent engineering achievements, we help customers recycle effluent water for use in cooling towers and incorporate automated monitoring systems that automatically select water bodies based on water quality conditions. This approach increases customers' use of recycled water, achieve plant water recycling targets, and reduces environmental pollution from wastewater discharge.

- Low-temperature sludge drying technology

Traditional sludge drying requires high temperature and pressure, consuming significant energy. We employ a specialized low-temperature, low-pressure drying method, allowing sludge moisture content to be adjusted as needed (for example, from 85% to 30%). Daily waste sludge can be processed within a short period (10–22 hours). This approach not only reduces energy consumption but also decreases the volume of sludge that must be outsourced for treatment.

- High-Efficiency Membrane Vapor Recovery Unit

Novatech actively collaborates with overseas technology developers to provide domestic enterprises with advanced pollution control equipment. In partnership with equipment manufacturers, we assisted in installing and operating a recovery system at the Qiaotou Supply Center and are currently preparing to implement the same technology for CPC Corporation’s naphtha storage tanks at the Linyuan Plant. This system captures potential vapor emissions from storage tanks, reducing the proportion of oil vapor released into the atmosphere. It can lower volatile organic compound (VOC) concentrations to below 300 PPM and achieve a high recovery efficiency of up to 95%. By significantly reducing air pollution, the system helps customers meet recycling and reuse goals while improving plant air quality. We support customers in integrating environmental protection and circular economy equipment and will continue to refine and advance this technology, working closely with clients to achieve sustainable operational transformation.

High-Value Energy Resource Recycling

High-tech facilities use numerous high-value chemicals that could pose significant risks to people and the environment if accidentally released. Through our products and technologies,Novatech provides customers with recovery and reuse systems for high-value raw materials in their manufacturing processes,

reducing costs while supporting environmental protection.Our key technologies include chemical waste liquid recovery and reuse equipment, aluminum etching solution recovery technology, and high-efficiency membrane vapor recovery units.

- Chemical Waste Liquid Recovery and Reuse Equipment

During production processes, high-tech and manufacturing industries consume substantial amounts of chemical raw materials, generating large volumes of chemical waste liquid.We adopt foreign waste liquid recovery technology and, using specialized recovery equipment, perform on-site recovery of high-unit-price waste liquids, converting them into raw materials that can be reused in the original manufacturing process. This approach effectively utilizes resources and prevents waste.

Related achievements include helping customers recover stripping solutions, process cleaning solvents, and tetramethylammonium from wastewater. We recover chemicals through distillation thermal methods and by utilizing the different boiling points of target chemicals. During the process, we also effectively recover thermal energy through high-efficiency heat exchange to reduce energy consumption.This technology allows customization and adjustment of the chemical recovery rate in the process, achieving a maximum solvent recovery rate of over 90%.

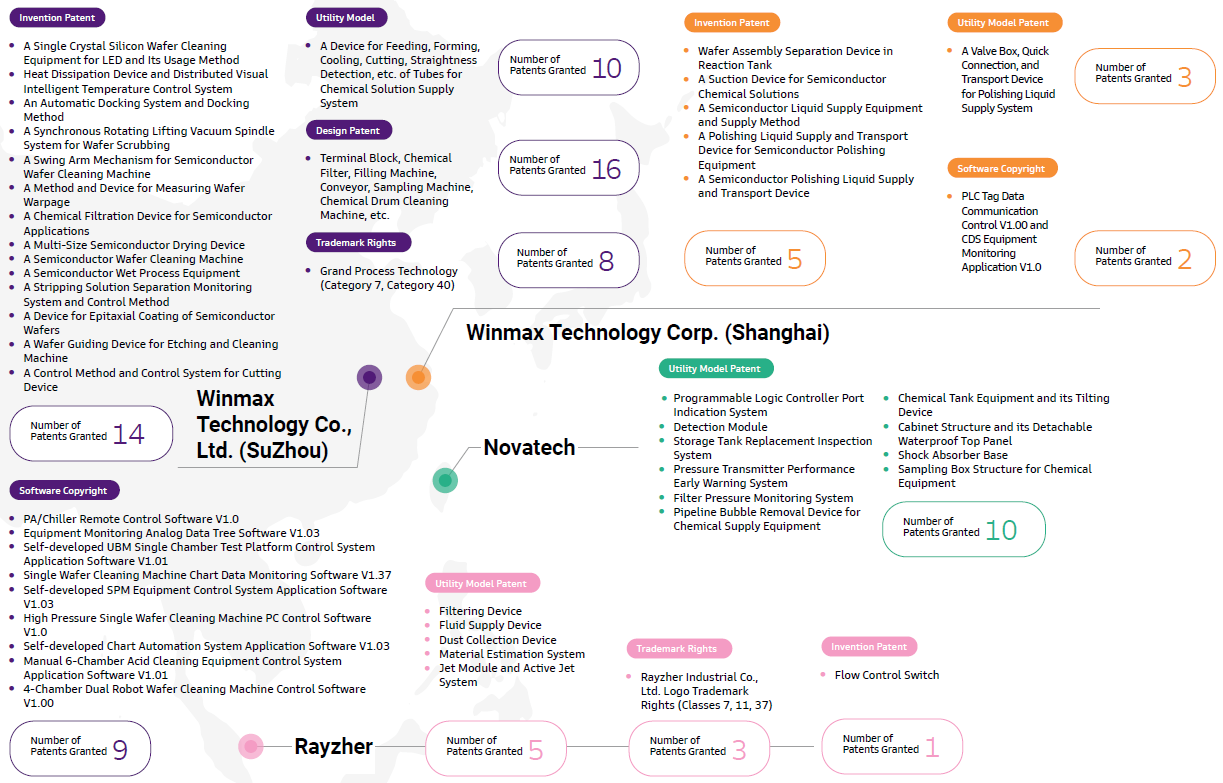

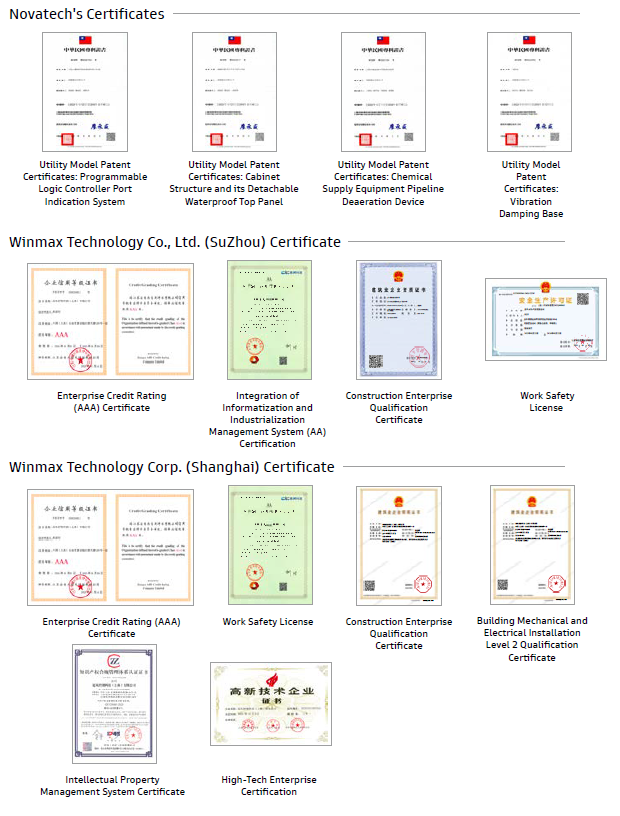

2024 Patent Items

Novatech and its subsidiaries, Winmax Technology Corp. (Shanghai) and Winmax Technology Co., Ltd. (SuZhou), establish research and development projects annually, focusing on improving existing equipment functions, meeting customer needs, and introducing new technologies. In 2024, the R&D investment amounted to NT$207,420,000. We actively invest in research and development of innovative products, continuously enhance our R&D capabilities and technical strength to address market demands, and maintain our leading technical position in the field of industrial process expertise. Our achievements are reflected in the number of patents applied for and obtained each year. In 2024, Novatech, Rayzher, and Chinese subsidiaries Winmax Technology Corp. (Shanghai) and Winmax Technology Co., Ltd. (SuZhou) collectively obtained 28 utility model patents, 20 invention patents, 11 software copyrights, 11 trademark rights, and 16 design patents,totaling 86 patent authorizations. Novatech has received multiple recognitions from government bodies and partners, demonstrating that Novatech and its subsidiaries possess industry-leading R&D technologies and competitive capabilities across both sides of the strait. We can rapidly design and manufacture solutions to meet diverse customer needs, resulting in long-term orders from high-tech industries on both sides of the strait.

Received Patent-Related Awards and Recognition in 2024

Number of Patents Granted in 2024