With the mission of becoming the Best Partner in High-Tech Industry Processes, Novatech continuously builds engineering expertise in process supply systems. Leveraging a highly competitive engineering team, we carefully select quality contractors and maintain strong partnerships to establish a robust supply chain. This approach allows Novatech to monitor raw material and outsourced engineering cost fluctuations in real time, effectively control project progress, costs,and construction quality, and deliver customers the highest-quality engineering services along with competitive project quotations.

Supply Chain Sustainability Management ┃ Management Approach

Significance and Meaning to the Company

- Supplier management process, policies, and implementation of supplier ESG self-assessment questionnaires.

- Using social and environmental criteria to screen and evaluate suppliers.

- Negative environmental and social impacts in the supply chain and actions taken.

Management Strategies

- Comply with the Supplier Code of Conduct commitment to not use metals sourced from conflict mineral regions.

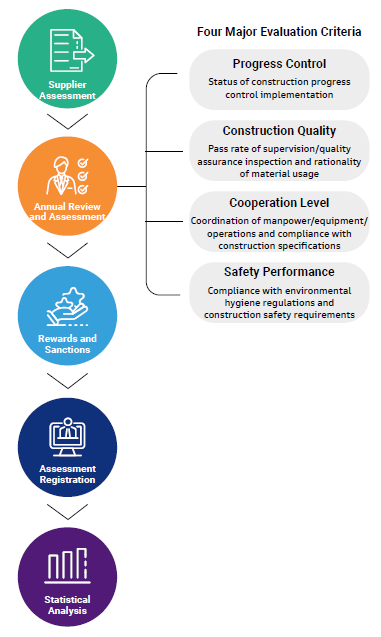

- Regularly evaluate on-site contractors based on four major aspects: work progress control, construction quality, cooperation, and workplace safety performance,as references for future collaboration decisions.

- Achieve win-win outcomes by promoting and communicating human rights, social, and environmental issues with partners periodically to jointly focus on sustainable development

Description of actual and potential negative and positive impacts

Positive:

- Implementing sustainable supply chain management not only ensures a stable supply of raw materials but also demonstrates positive external influence and enhances corporate reputation through improving overall supply chain sustainability performance and compliance with international standards.

Negative:

- ESG-related issues in the supply chain can cause environmental harm or human rights violations,leading to negative perceptions of the company among

customers, investors, and the public. This may result in revenue loss and potentially undermine the stability of the entire supply chain.

Action Plan/Resources

- The Procurement Department has completed signing the Agreement of Subcontractor Commitment with the top 10 suppliers and expanded it to 50% of tierone suppliers.

- The Procurement Department evaluates and classifies suppliers according to the supplier control procedure.

- Establish green procurement principles and actively communicate with the value chain.

- Conduct surveys on key suppliers' ESG implementation,impact assessment, and actions taken.

Policy/Commitment

- Supplier Control Procedures.

- Signing of Agreement of Subcontractor Commitment.

- Supplier Management Mechanism.

Responsibility

- Procurement Department, Engineering Department, Project Department.

* This material topic has no actual activities or business relationships involving negative impacts in the current year.

Supply Chain Overview

Novatech views suppliers as key partners and an indispensable part of its supply chain team. We are committed to maintaining long-term cooperative relationships with domestic and international suppliers to jointly build a stable and sustainable supply chain.

The Upstream, Midstream, and Downstream Relationships in High-Tech Industry Process Supply Systems

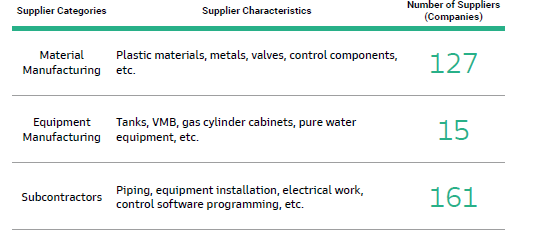

Number of Suppliers by Category in 2024

Novatech’s suppliers can be categorized into three categories: material manufacturing, equipment manufacturing, and subcontractors. We firmly believe that successful business operations rely on coexistence, co-prosperity, and mutual growth with supplier partners, and have always regarded them as strategic partners. Novatech’s main production and operational site is in Taiwan. To promote local industrial clusters and enhance regional economic development, except for some bulk chemicals that are technically controlled by overseas suppliers and cannot be procured locally, we have made every effort to choose local suppliers for collaboration. In 2024, there were 303 suppliers with transaction records.

Note: If a supplier operates across multiple categories, for internal management purposes, they will be counted in each category rather than being assigned to a primary category and excluded from others.

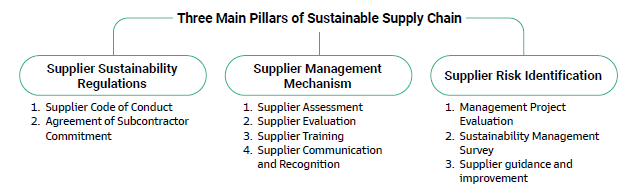

Supply Chain Sustainable Development

In addition to ensuring supplier product quality, pricing, and delivery times, the Company requires suppliers to implement corporate social responsibility, align with the United Nations Sustainable Development Goals, and maintain proper risk management and business continuity plans. The supply chain is divided into three main pillars:sustainability regulations, management mechanisms, and risk identification, implementing regulations and responsible procurement to jointly maintain a stable and developing supply chain.

Supplier Sustainability Regulations

In strict adherence to the Principles of Ethical Behaviors and Ethical Corporate Management Best Practice Principles,Novatech requires compliance with the Supplier Code of Conduct, which prohibits the following behaviors: any bribery or acceptance of bribes, offering or accepting unreasonable gifts, entertainment or other improper benefits, infringement of trade secrets, trademarks, patents,copyrights and other intellectual property rights, and declares a commitment that neither the Company nor its suppliers will accept metals sourced from conflict minerals regions.

When collaborating with suppliers, an Agreement of Subcontractor Commitment must be signed. This agreement includes corporate social responsibility requirements, such as compliance with local laws and international safety and environmental regulations, prevention of exposure to or contamination by harmful controlled substances during manufacturing and transportation, prohibition of child labor, and avoidance of any form of labor discrimination.

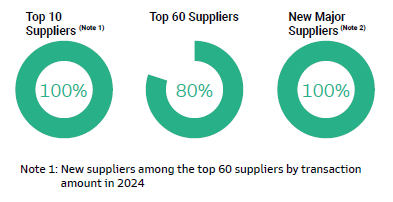

In 2024, we completed the signing of the Agreement of Subcontractor Commitment with 48 suppliers, achieving a 100% signing rate among the top 10 suppliers by

transaction value in Taiwan and China, and an 80% signing rate among the top 60 suppliers by transaction value.

2024 Signing Rate of Agreement of Subcontractor Commitment

Supplier Management Mechanism

Supplier Assessment

- All suppliers must pass the assessment process and comply with the Supplier Code of Conduct.

Supplier Evaluation

- Conduct periodic assessments of business management and ESH management systems at equipment assembly plants.

- Conduct quarterly progress control evaluations for on-site construction contractors.

Supplier Training

- Hold toolbox meetings before contractors enter the construction site daily.

Supplier Communication and Recognition

- Invite suppliers with outstanding performance and exceptional contributions to attend the Company's annual year-end banquet.

Supplier Assessment

For new suppliers, in addition to collecting basic supplier information, we require them to complete a Supplier Evaluation Form. Selection criteria include product brands, engineering performance, waste disposal and treatment, workplace environment monitoring, construction quality certifications,regular fire safety inspections, and automatic inspection equipment. These are included as evaluation items. Novatech also specifies in order terms that any violation of relevant

regulations by suppliers will result in contract termination.

Supplier Evaluation

We have established a comprehensive supplier evaluation and responsible procurement mechanism as the basis for selecting excellent contractors. We regularly conduct quality assessments and replacement evaluations of contractors based on four main criteria: progress control, construction quality, construction

cooperation, and safety performance. Furthermore, through periodic advocacy and communication on human rights, social, and environmental issues, we strengthen suppliers’sustainability awareness.

Supplier Management Evaluation Process

Supplier Training

We periodically conduct educational training and workshop meetings, guiding communication through different formats. The courses include regulatory risks, ethical standards, workplace safety and health. Before contractors enter construction sites each day, toolbox meetings are held to promote environmental safety and health policies and construction regulation guidelines to suppliers.

Supplier Communication and Recognition

Outstanding and high-contributing suppliers are invited to the Company’s annual year-end banquet,where the Company communicates its sustainability philosophy and objectives.

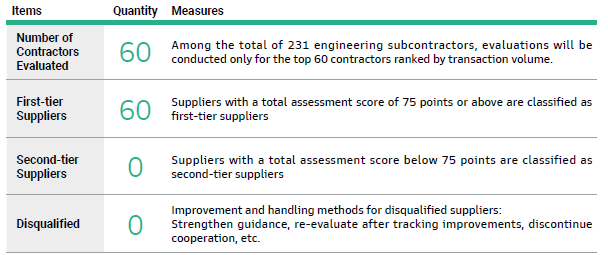

Supplier Risk Identification

Through supplier EHS assessment, construction quality performance evaluation, and supplier ESG self-assessment questionnaires, Novatech provides guidance and improvement measures for suppliers with potential high risks to ensure effective risk control or reduction. The Company has 231 general contractors for engineering subcontracting. In 2024 evaluations were conducted for the top 60 contractors based on transaction volume.

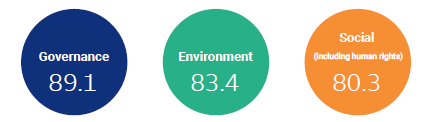

Sustainability Management Survey

To ensure effective supplier management, Novatech conducted its first Supplier ESG Self-Assessment Survey in 2024, targeting 35 key suppliers selected from the top 60 vendors. The survey covers aspects of governance, environment, and social issues, aiming to identify suppliers’ sustainability implementation status, understand risk points, and prepare for proactive responses.

In 2024, 35 suppliers participated in the ESG self-assessment survey, achieving a 100% response rate.The average scores for each aspect were: Governance 89.1 points, Environment 83.4 points, and Social (including human rights) 80.3 points. All suppliers’ self-assessment questionnaire scores were above 80 points.

Supplier guidance and improvement

The Company will continue to monitor major suppliers and conduct unscheduled on-site audits to inspect suppliers’ performance. We will also continue to evaluate suppliers’corporate social responsibility practices and supervision to foster sustainable partnerships and achieve mutual growth.

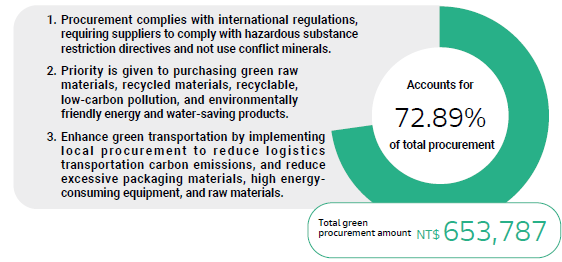

Green procurement and environmental protection expenditure

To promote environmental sustainability, Novatech upholds green procurement principles and strives to reduce the environmental impact of operational activities. We purchase office equipment with green environmental protection or energy-saving certification labels, promoting carbon emissions reduction. In 2024, the total green procurement amount was NT$653,787, accounting for 72.89% of total procurement, including replacement of inverter air conditioners with eco-labels, eco-friendly light tubes, energy-efficient fans, and green office supplies (such as recycled paper).

Green procurement principles

Product packaging and transportation

To promote energy-saving and carbon reduction policies and mitigate environmental harm caused by excessive product packaging or long-distance transportation, Novatech adopts green transportation principles by following these four operational guidelines.

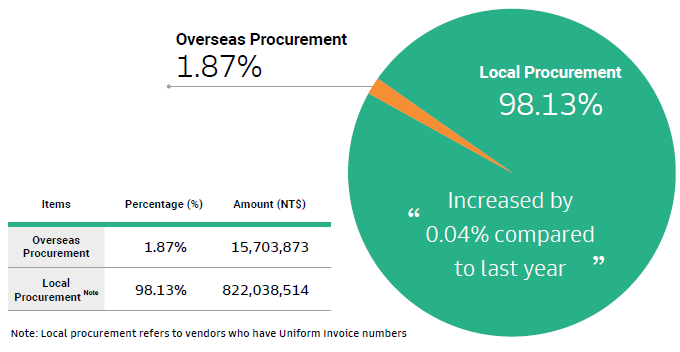

Local procurement

Suppliers and contractors are key business partners of Novatech. Through effective communication,close cooperation, and appropriate management supervision, the Company can work together with suppliers toward sustainable operations. We firmly believe that, as a responsible corporation, we should contribute to local economic development. Therefore, in line with the purpose of assisting local development and developing the local economy, we prioritize using local material suppliers and appointing local contractors when selecting partners for engineering projects. In 2024,Novatech’s local procurement from Taiwan regional vendors (note) was 98.13%. Due to shortages of foreign raw materials and significantly increased transportation costs, Novatech actively communicated with customers to promote local procurement, resulting in a 0.04% increase in local procurement ratio compared to last year’s 98.09%.

Novatech actively promotes green supply chain by partnering with suppliers to assess whether their equipment adopts energy-saving or high-efficiency models. We also increase collaboration with partnering vendors to encourage their voluntary participation in green supply chain initiatives. In the future, Novatech will collect data and performance metrics on suppliers’ adoption of energy-efficient equipment to accelerate supplier advancement.