Semiconductor Grade Process Chemical & Packing System

feature of product

1.4L&20L barrel cleaning equipment:

- This model adopts DI backwash + N2purge.

- It adopts PLC control, touch screen man-machine interface display, easy to operate. The number of cleaning barrels can be customized according to customer needs, and the cleaning nozzles can be customized to achieve all-round cleaning without dead ends.

- This production line includes automatic cleaning, automatic filling, automatic locking and labeling, automatic assembly line, manual handling and packing, and supporting laboratory sampling analyzer counter equipment. Provide customers with a complete plant with full automatic assembly line equipment.

- Customize the feasibility of the whole plant planning program according to customer needs, and provide customers with safe, reliable and stable production equipment.

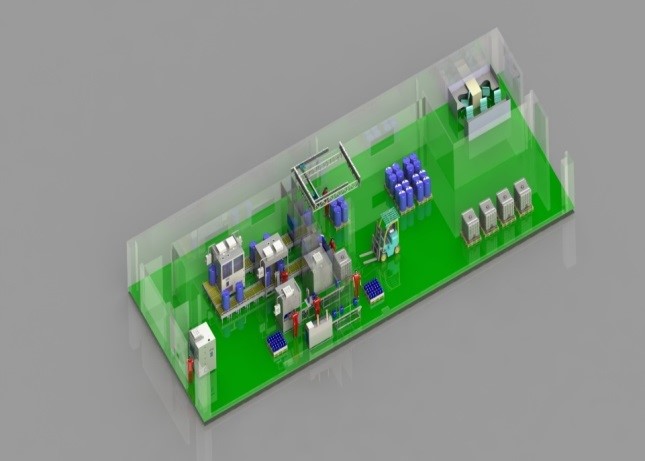

2. Visualized 3D design planning of the whole plant:

- This production line includes automatic cleaning, automatic filling, automatic locking and labeling, automatic assembly line, manual handling and packing, and supporting laboratory sampling analyzer counter equipment. Provide customers with a complete plant with full automatic assembly line equipment.

- Customize the feasibility of the whole plant planning program according to customer needs, and provide customers with safe, reliable and stable production equipment.

3.200LDrum online automatic cleaning equipment:

- Realize the online automatic cleaning function, and automatically set the best cleaning angle to achieve the best cleaning effect. Design barrel mouth and tooth mouth cleaning function; custom-made cleaning nozzles to achieve all-round cleaning without dead ends. It adopts PLC control, touch screen, man-machine interface display, easy to operate.

- It is used for the cleaning of acid barrel accessories and barrels to realize the online automatic cleaning function. The cleaning of accessories requires the design of ultrasonic cleaning function, and the design of a collection and control system for high-concentration residual acid. The cleaning machine meets the CLASS 100 cleanliness level in a dust-free environment.

4.200L chemical automatic Drum barrel filling line:

- The filling area meets the CLASS100 cleanliness level, the filling gun and the filling valve are foolproof design, the filling gun exhaust design, the high-precision fully enclosed electronic weighing design is adopted, and the relevant functions are customized according to customer needs.

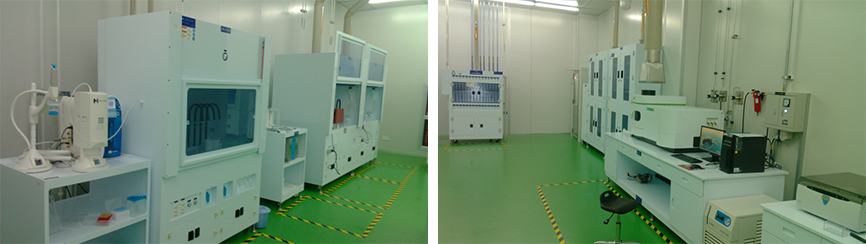

5. Laboratory sampling analyzer counter equipment: