Waste Chemical Recovery & Supply System

Specialty

-

High recovery rate (over 90%) and excellent quality

-

Concentration can be adjusted without using electronic grade solvents

-

Can be started in a short time

-

Fully automated operation

feature of product

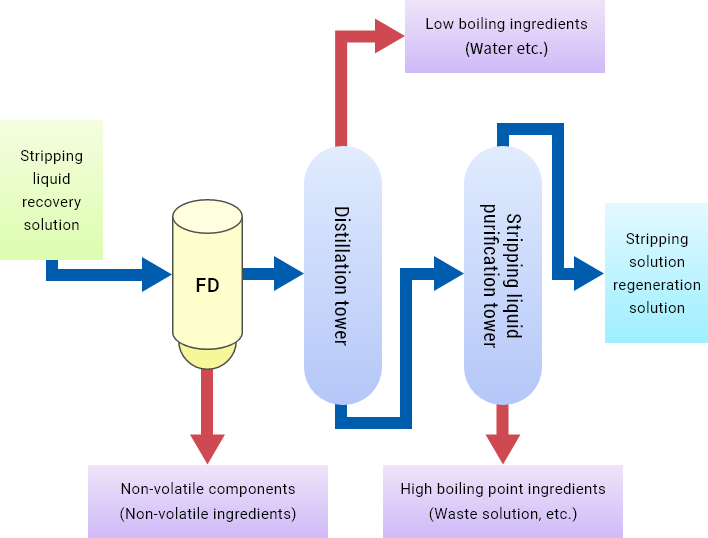

Principle of Stripper Recycle System:

In the LCD screen production, large amount of stripping solvent is consumed during the volatile resistance components stripping process.The waste solution from this stripping process contains three main impurities: nonvolatile (volatile resistance components), low boiling point (water, etc.), and high boiling point components.SRS separates and recycles the stripping solvent from the waste effectively.In this process, the separated volatile resistant components can be liquidified into low viscosity fluid.As the stripping solution evaporates, heavy metal components percipitates and can be recycled with high efficiency.

- Non-volatile components is first separates from the recovered stripping solution by the falling film dryer (FD).

- The remaining recovered stripping solution is then flowing into the distillation column, where the low boiling impurities are separated.

- In the stripper refining column, the stripping solution is vaporized and thus separated from the remains (other high- boiling components).

Specification list

MEA-DMSO waste stripping solvent (containing 10% water and 2% non-volatile content) treatment is used as the standard method.

| Model | Approximate size | Processing capacity |

|---|---|---|

| SRS-20 | W4000 × D1700 × H2500 | 20 L/hr |

| SRS-150 | W6450 × D2200 × H7150 | 150 L/hr |

| SRS-250 | W6450 × D2500 × H7800 | 250 L/hr |

| SRS-500 | W11000 × D3200 × H10000 | 500 L/hr |

| SRS-750 | W11000 × D3200 × H10000 | 750 L/hr |

| SRS-1000 | W11000 × D3200 × H10000 | 1000 L/hr |

| SRS-1300 | W13000 × D3200 × H12800 | 1300 L/hr |

Application field

The system is used to recover the stripping solvent used in the production process of LCD screens. In recent years, as the area of liquid crystal display screens has increased, the amount of solvents has also increased. Therefore, it is necessary to reduce costs by reusing solvents and adopting some environmental protection measures. SRS has a high recovery rate and is easy to operate, which can meet your needs.