With extremely high requirements for quality and expertise, engineering services entail a strong supply chain. The Novatech group has years of experience in engineering supply systems. We maintain good relationships with our suppliers to keep abreast of the prices of raw materials and outsourcing services, as well as progress of construction. Therefore, we are able to control construction costs and quality effectively, further providing clients quality engineering services and competitive pricing. We have a sound supplier evaluation system as a basis for selecting outstanding suppliers and contractors. We also communicate our respect for human rights, social and environmental issues to our partners from time to time in hopes of achieving sustainable development together with the supply chain. In the future, the Company will continue perfecting the supply chain locally to improve productivity, quality and competitiveness for business sustainability.

Management Approach

| Disclosure | Novatech's Practices |

|---|---|

| Importance | Select quality suppliers and contractors to provide high-end engineering services for clients |

| Management strategies |

|

| Policies/ commitments | Supplier Management Process, Procurement Management Process, Code of Ethical Conduct, and Ethical Corporate Management Best Practice Principles |

| Goals and targets |

|

| Responsibility | Procurement Department, Engineering Department, and Project Department |

| Resources | Joint supplier evaluation system |

| Grievance mechanisms | Company website: Contact Us/Business Contact Suppliers contact: Vickie Tu E-Mail:Vickie_Tu@novatech.com.tw Ways of communication: email, telephone and meetings |

| Action plans |

|

| Effectiveness assessment |

|

Our Supply Chain

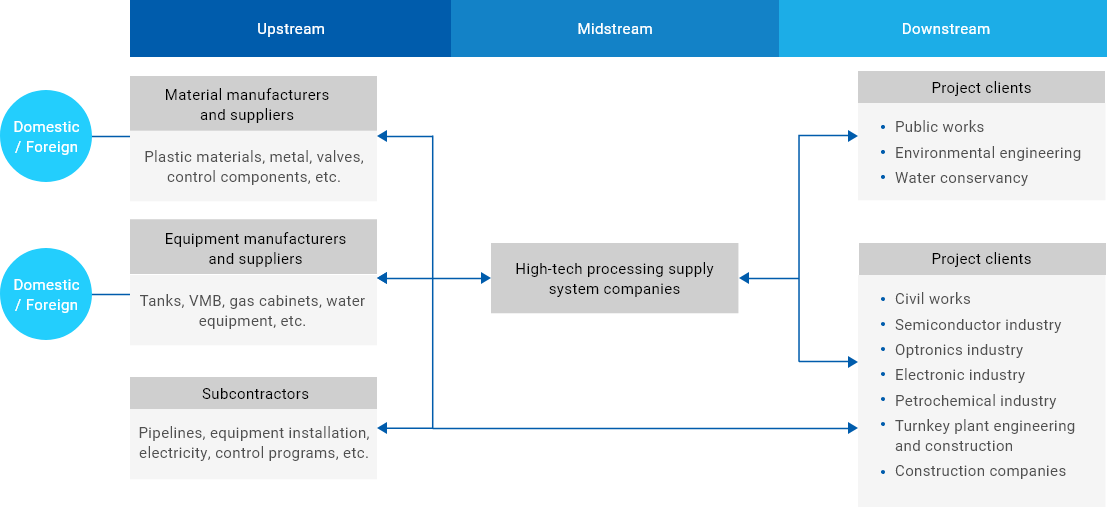

ovatech sells, engineers, and constructs high-tech processing equipment. Our high-tech processing supply system falls between project clients and project materials, equipment, and project outsourcers, providing clients process supply system equipment and project services. The association between upstream, midstream and downstream is shown in the following drawing:

Association between Upstream, Midstream and Downstream of the High-Tech Processing Supply System

Novatech always regards suppliers as strategic partners. We firmly believe that the survival and prosperity of a business rests on good supplier partnerships. Our suppliers are divided into three main categories: material manufacturing, equipment manufacturing and subcontractors. We had 405 suppliers in 2019.

| Type and Number of Suppliers in 2019 | |||

|---|---|---|---|

| Type of Suppliers | Material Manufacturers | Equipment Manufacturers | Subcontractors |

| Supplier characteristics | Plastic materials, metal, valves, control components, etc | Tanks, VMB, gas cabinets, water equipment, etc. | Pipelines, equipment installation, electricity, control programs, etc. |

| Number of suppliers | 194 | 15 | 196 |

Local Procurement

For Novatech, suppliers and contractors are important business partners. Only by good communication, close cooperation and proper management and supervision can the Company advance on sustainable development together with suppliers. We are convinced that it's incumbent on a company to drive economic activities locally. For the purpose of supporting the local development and economy, Novatech gives priority to local material suppliers when selecting partners for construction projects, and appoints local contractors to carry out engineering planning. In 2019, 67.78% of our materials were sourced from Taiwanese suppliers (Note).

| Type of Procurement | Percentage (%) | Amount (NT$) |

|---|---|---|

| Overseas | 32.22 | 439,410,808 |

| Local Note | 67.78 | 924,359,821 |

Note: Suppliers registered with a unified business number

Supplier Management Policy

The Company regards every suppliers as an important partner. We are committed to maintaining long-term relationships with our suppliers at home and abroad in hopes of building a stable and sustainable supply chain. Novatech strictly abides by the Ethical Corporate Management Best Practice Principles and the Code of Ethical Conduct. We also require that our suppliers should not bribe or take bribes, provide or accept unreasonable gifts, entertainment or other improper benefits, or infringe on trade secrets, trademark rights, patent rights, copyrights and other intellectual property rights. We declare and promise that we will not use metals in conflict and that we will requests suppliers to comply strictly.

In addition to ensuring the quality, delivery and prices of products provided by suppliers, the Company also urges suppliers to fulfill their corporate social responsibilities for environment, health and safety, human rights and integrity. We deal with suppliers and contractors in a fair and open manner while implementing risk management and business continuity planning. In our opinion, good quality, reasonable price and proper service are the very basis for supplier partnerships to last long. To maintain long-term partnerships with our suppliers, we ask them to sign the "Supplier Commitment" that advances a win-win situation for both the Company and the suppliers.

In 2019, we added corporate social responsibility clauses to the "Supplier Commitment" to enlist suppliers and contractors in achieving corporate citizenship together with us. The "Supplier Commitment" stipulates that suppliers should obtain product certifications or licenses, comply with local laws and international safety and environmental regulations, avoid contacting or mixing hazardous or controlled substances in course of manufacturing and transportation, and disallow child labor and any form of workplace discrimination. In 2019, our top ten suppliers (Note) signed the "Supplier Commitment." We expect to have all tier 1 suppliers sign the "Supplier Commitment" in the future.

Supplier Evaluation

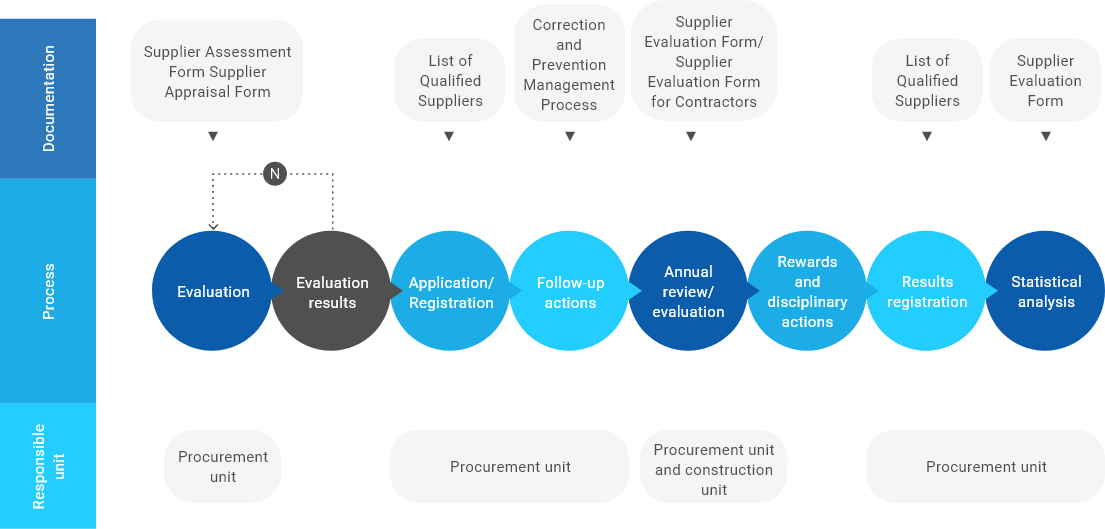

All suppliers are required to pass the supplier evaluation and comply with the "Supplier Code of Conduct."

Supplier Audit

The procurement staff, in conjunction with the occupational safety personnel, visit the equipment assembly plant from time to time to conduct evaluations on business management, manufacturing technology, equipment measurement, quality and EHS management.

The project leader conducts four evaluations in point of construction progress control, construction quality, degree of cooperation, and occupational safety on on-site contractors every month.。

Supplier Training

Every day before contractors enter the construction site, a toolbox meeting is held to communicate the EHS policy and construction notes to the contractors.

Supplier Communication and Recognition

At the year-end party, we invite suppliers with outstanding performances and contributions to celebrate with us and encapsulate Novatech's vision and goal for business sustainability.

Supplier Evaluation Process

Four Evaluation Items

Construction progress control

Construction progress control

Construction quality

Pass rate on supervision/ quality assurance inspection and appropriateness of materials used

Degree of cooperation

Manpower/machinery/work coordination and compliance with construction instructions

Occupational safety

Occupational safety

| Supplier Evaluation Results in 2019 | ||

|---|---|---|

| Item | Quantity | Description |

| Contractors evaluated | 60 | The total number of construction contractors was 196. |

| Tier 1 suppliers | 60 | The total score on assessment items was 75 points or more. |

| Tier 2 suppliers | 0 | The total score on assessment items was 74 points or less. |

| Unqualified suppliers | 0 | Corrective actions (e.g., termination of cooperation, counseling and reevaluation after corrective actions taken) were taken. |

Status of Suppliers on-Site Audit in 2019

Number of suppliers receiving on-site audit

Percentage of suppliers receiving on-site audit

Improvement rate